I created this project after being inspired by Hendo's hover board. This was my Senior Design Project. The goal was to maximize the magnetic levitation force and create a vehicle that could levitate.

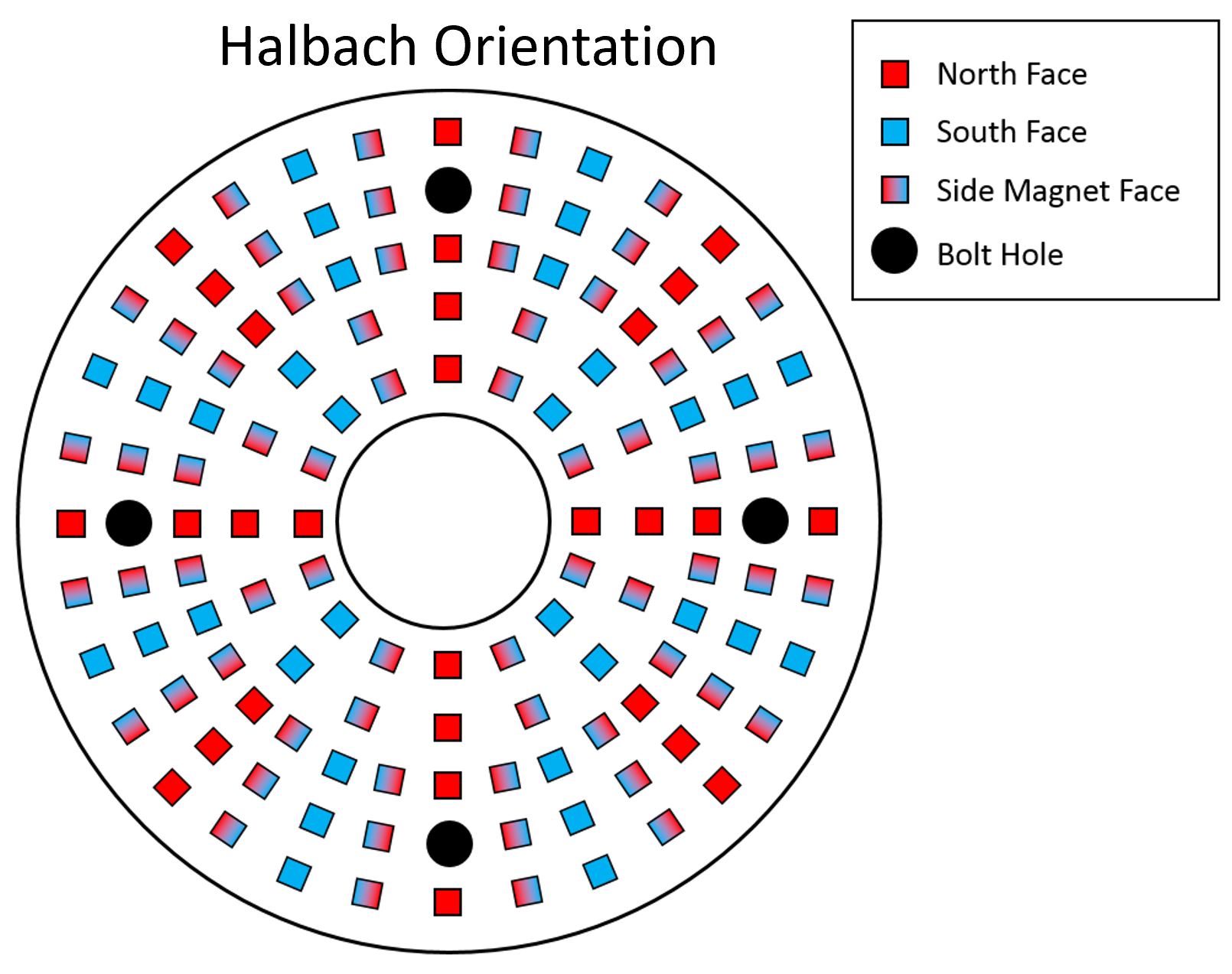

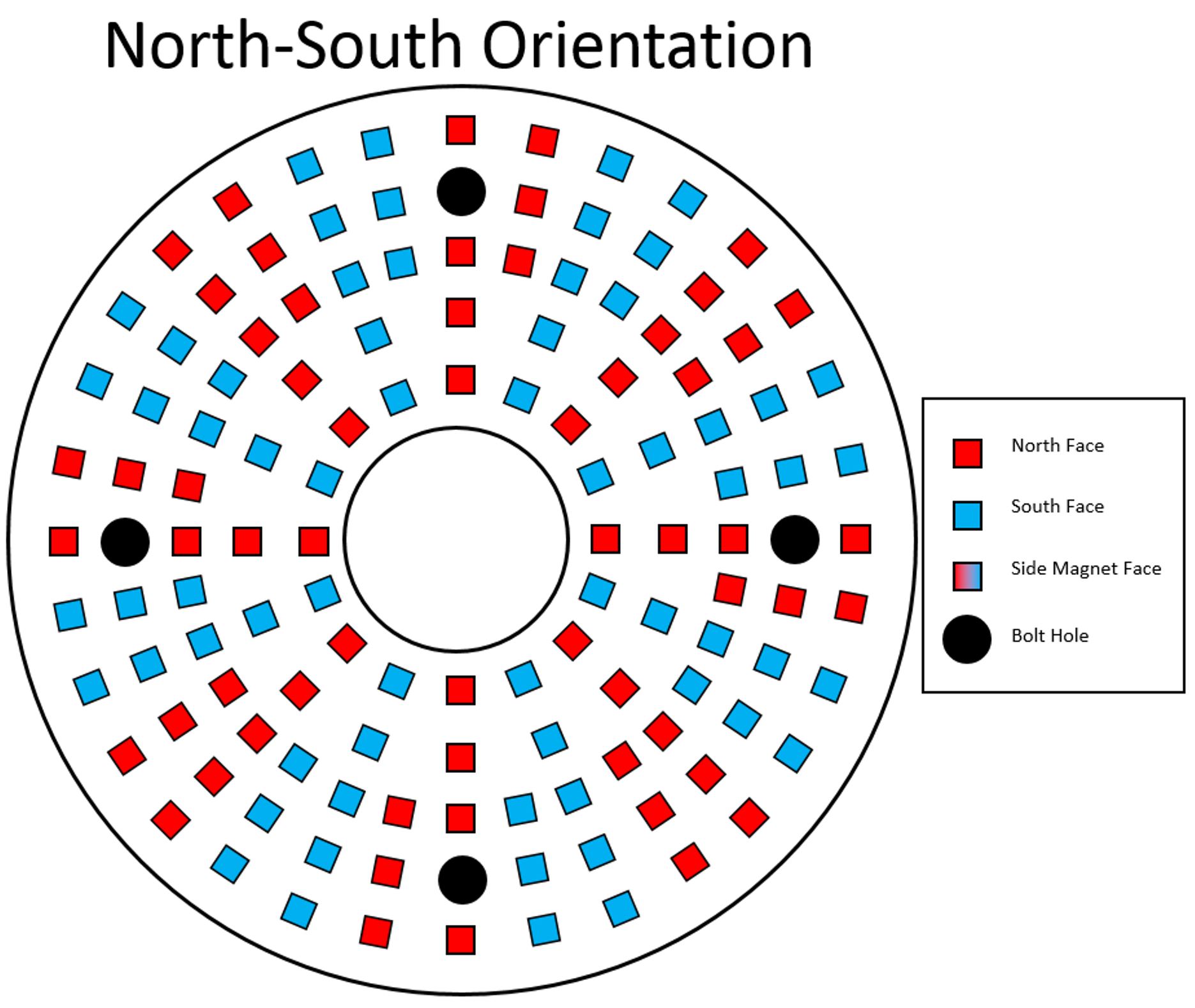

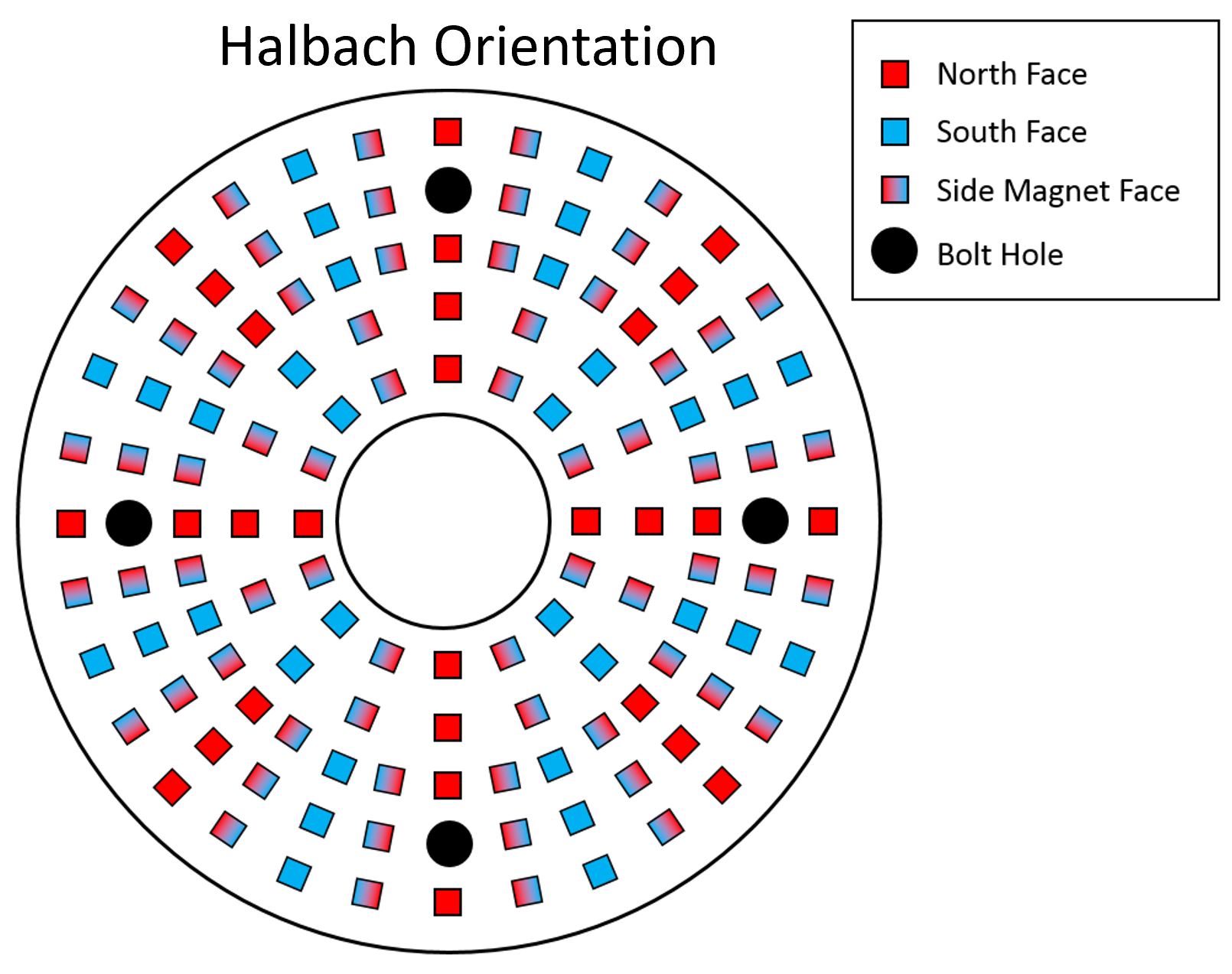

The primary concept behind this type of magnetic levitation it to alternate the magnetic field rapidy above a non-ferrous, conductive surface. This can be done by radially alternating the permanent magnet orientation as seen in the below illustration. The Halbach array provides the greatest difference in magnetic fields and would provide the highest repulsion force. There were many factors that needed to be optimized to ensure the maximum repulsion: distance to substrate, rotation rate, substrate material, thickness of substrate, and magnetic disc orientation. The repulsion force with the 5mm magnetic cubes in the disc did not produce a significant force. I tried going to bigger magnets next.

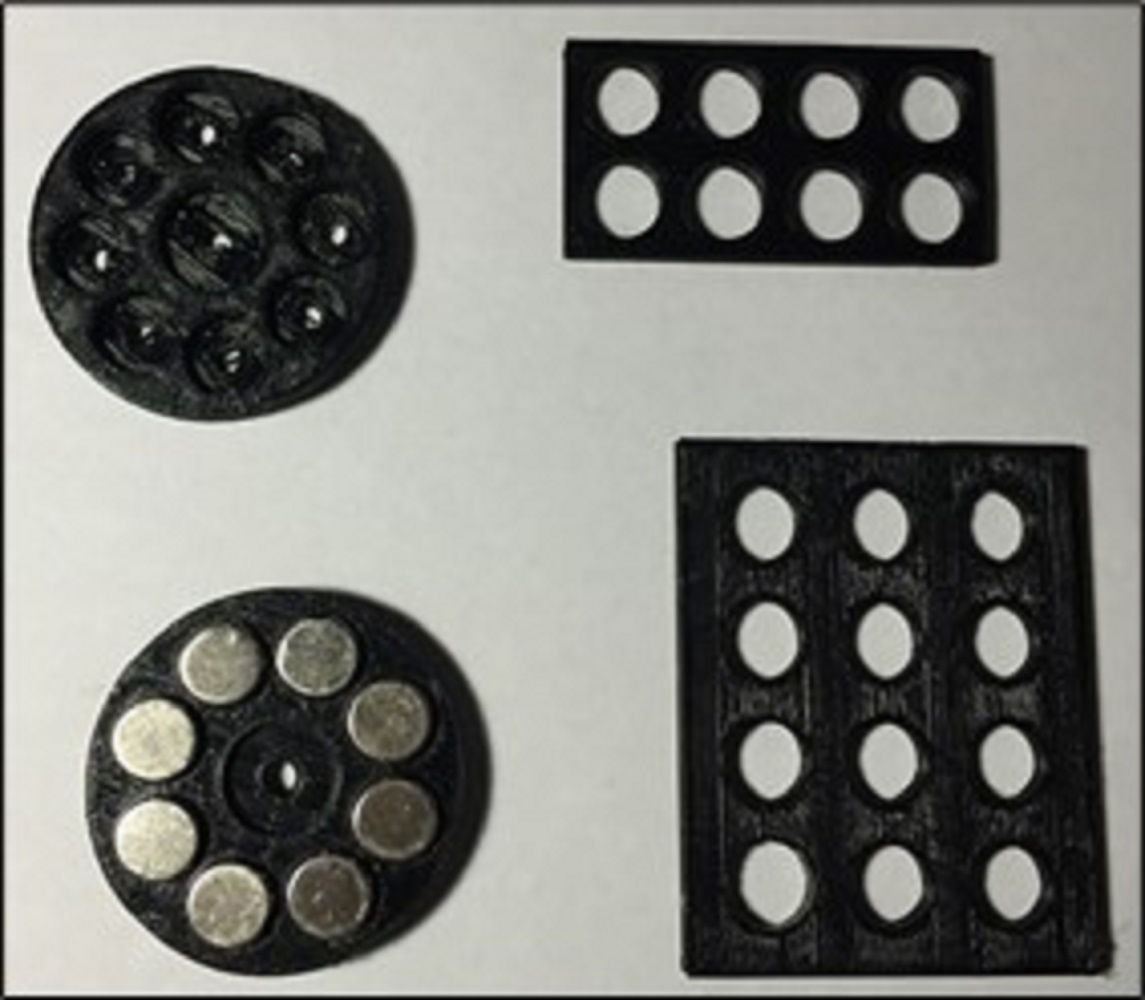

The repulsion force with the 5mm magnetic cubes in the disc did not produce a significant force. I tried going to bigger magnets next.

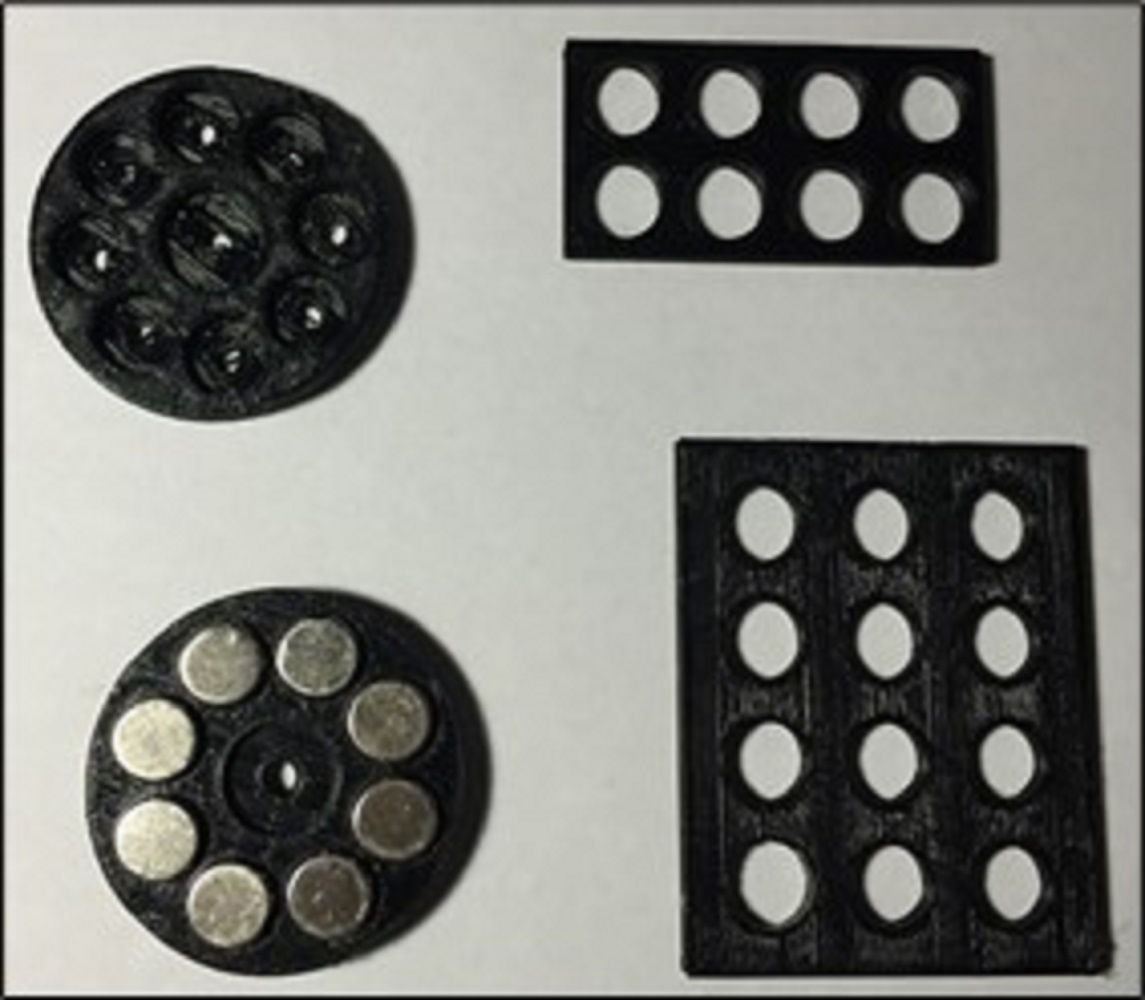

I printed a grid with slightly different diameters to select the best press fit.

I printed a grid with slightly different diameters to select the best press fit.

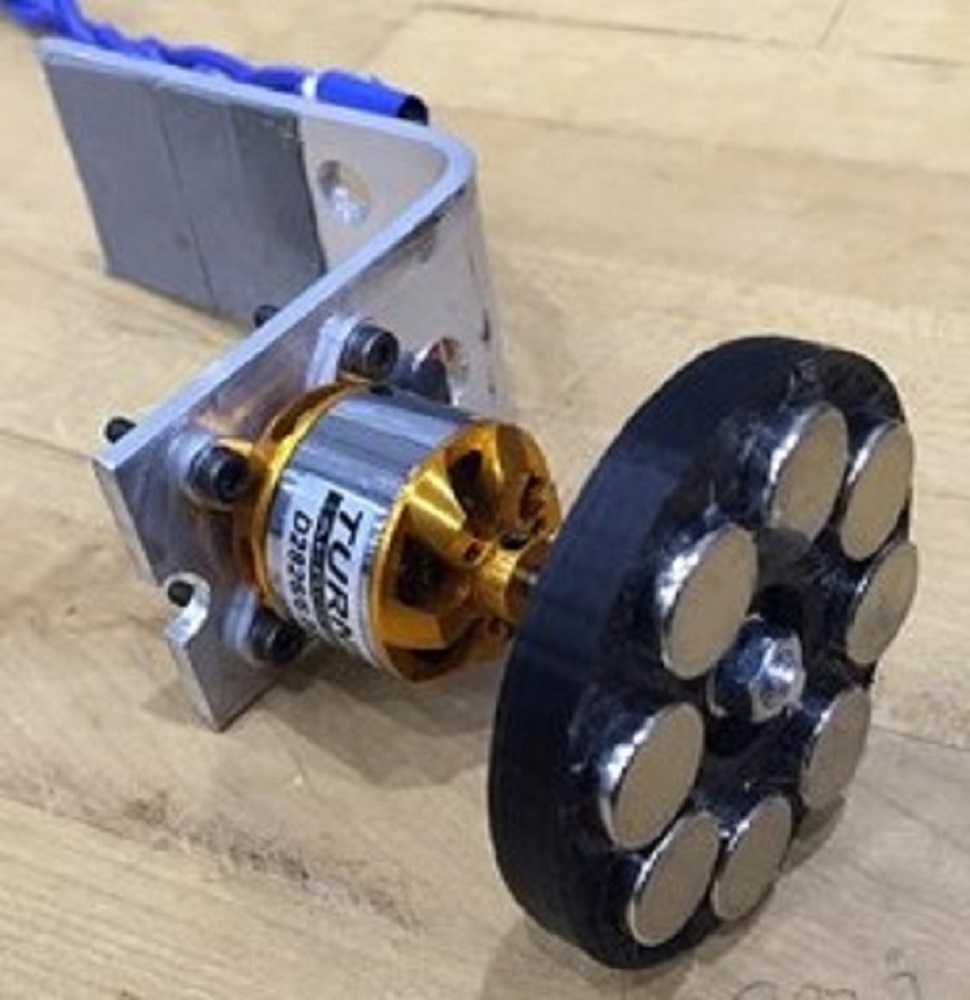

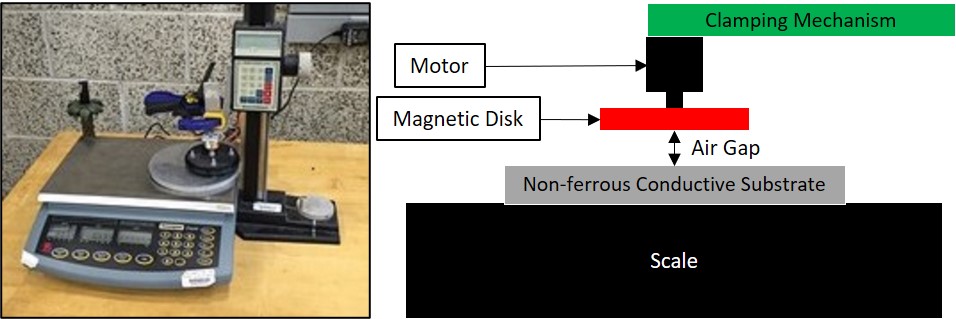

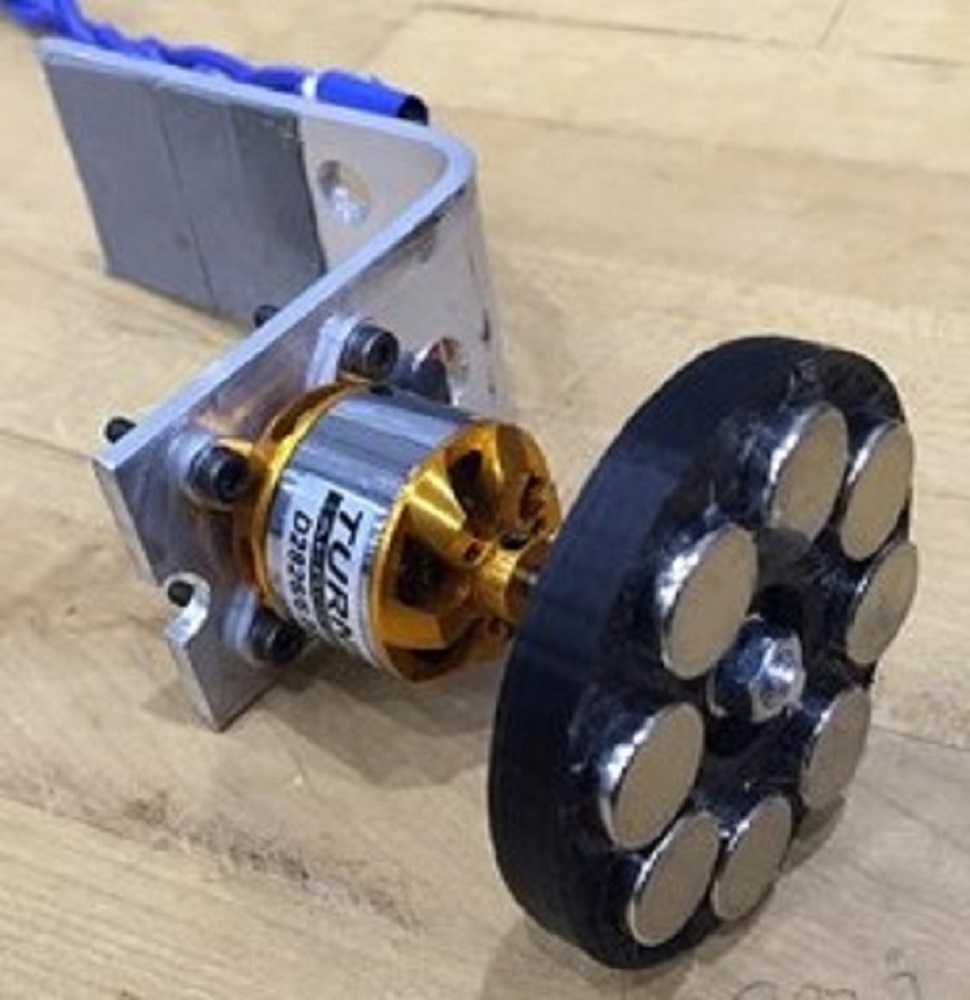

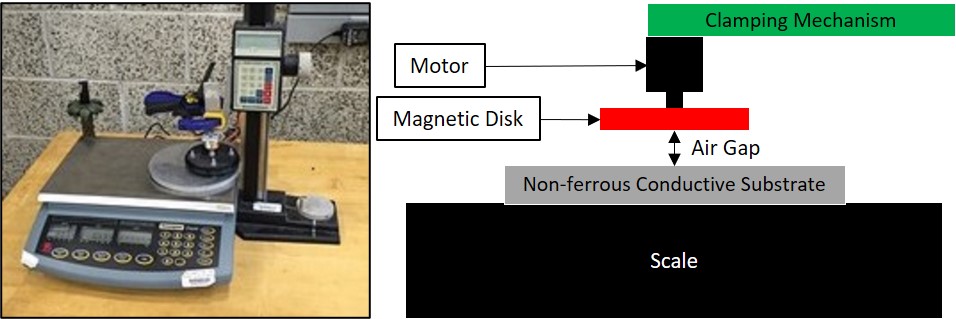

This fixture was made to test the repulsion. in order to optimize the variables.

This fixture was made to test the repulsion. in order to optimize the variables.

A scale was used to see the repulsion force provided. After much testing, the optimal variables that create the highest repulsion force are: closest to substrate, thickest substrate, and the most conductive substrate.

A scale was used to see the repulsion force provided. After much testing, the optimal variables that create the highest repulsion force are: closest to substrate, thickest substrate, and the most conductive substrate.

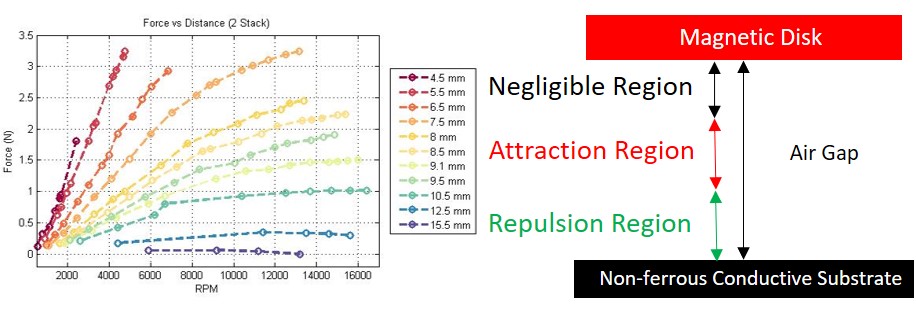

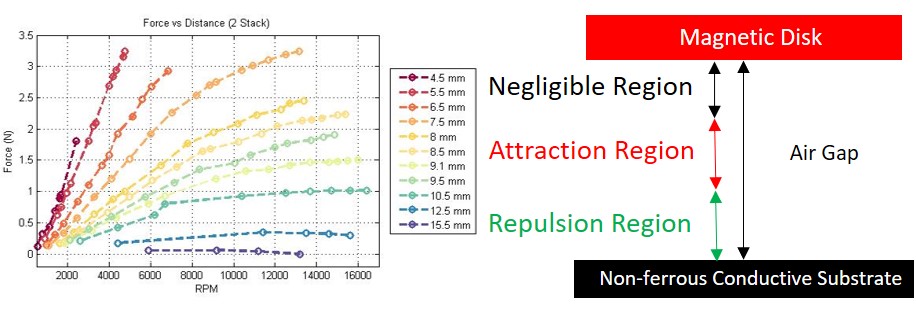

An unexpected finding is that there is an attaction zone between the repulsion and negligible regions. This was found when the scale kept showing an error. The scale was not zeroed after the substrate was added, thus allowing me to see the weight decrease when the disc spun in the attraction region.

An unexpected finding is that there is an attaction zone between the repulsion and negligible regions. This was found when the scale kept showing an error. The scale was not zeroed after the substrate was added, thus allowing me to see the weight decrease when the disc spun in the attraction region.

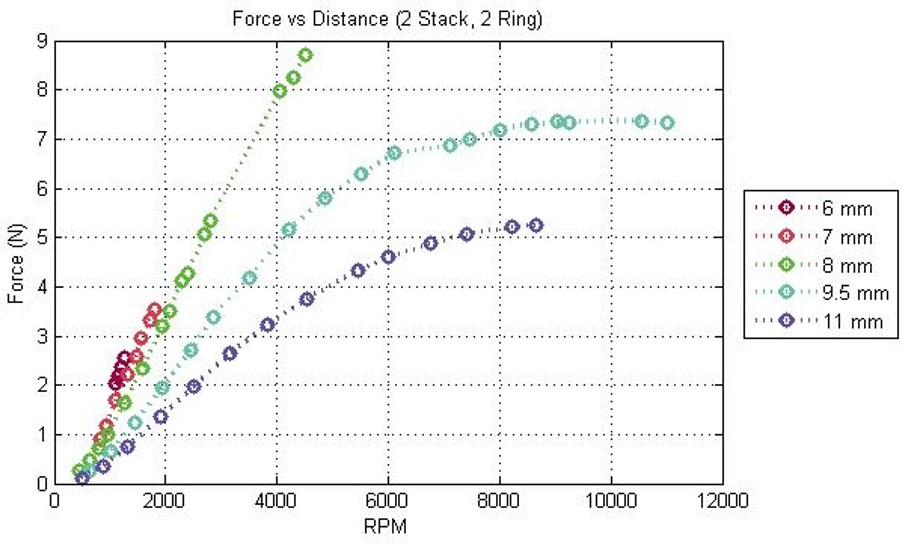

The other important finding was that due to the resistance of the rotating magnetic disc (the higher repulsion force, the more resistance), the RPMs would be limited during testing at fixed distances, as seen in the below plot.

This meant landing feet needed to be added to the vehicle that would allow the discs to have minimal resistance when starting up, but not position the vehicle far enough from the substrate to lack the repulsion force needed to levitate the vehicle.

The other important finding was that due to the resistance of the rotating magnetic disc (the higher repulsion force, the more resistance), the RPMs would be limited during testing at fixed distances, as seen in the below plot.

This meant landing feet needed to be added to the vehicle that would allow the discs to have minimal resistance when starting up, but not position the vehicle far enough from the substrate to lack the repulsion force needed to levitate the vehicle.

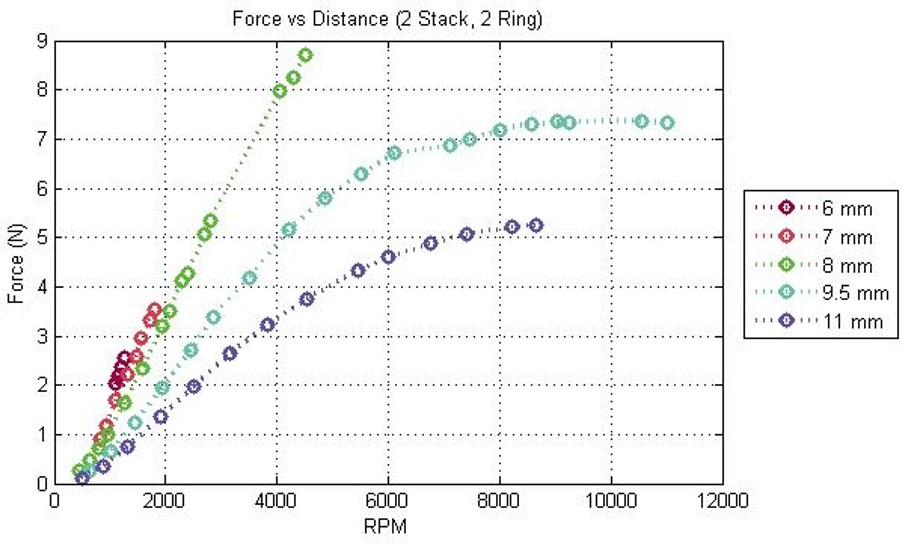

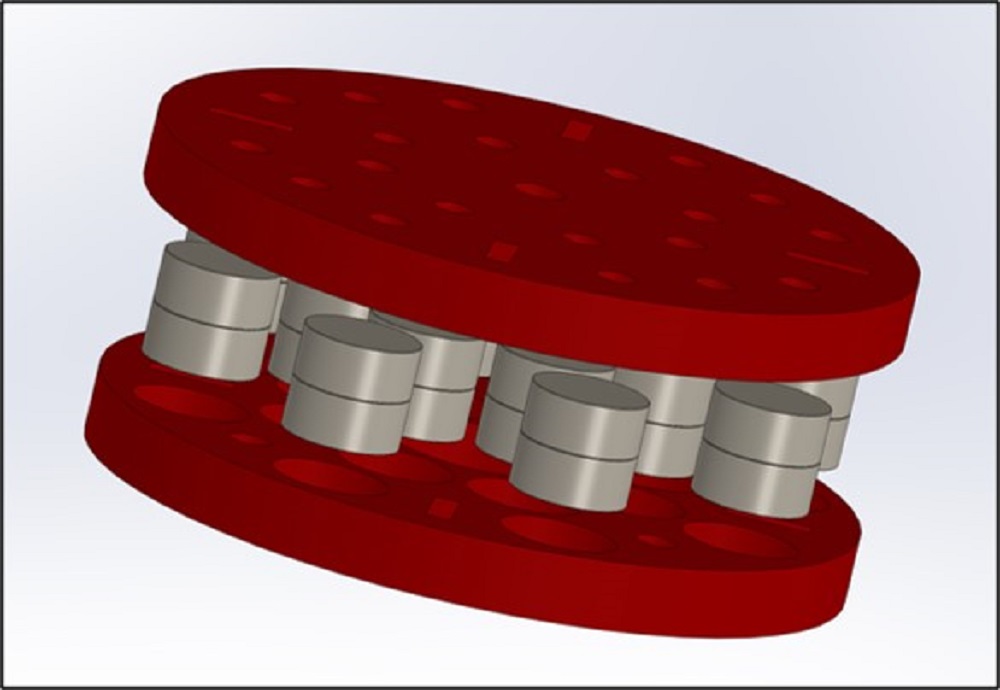

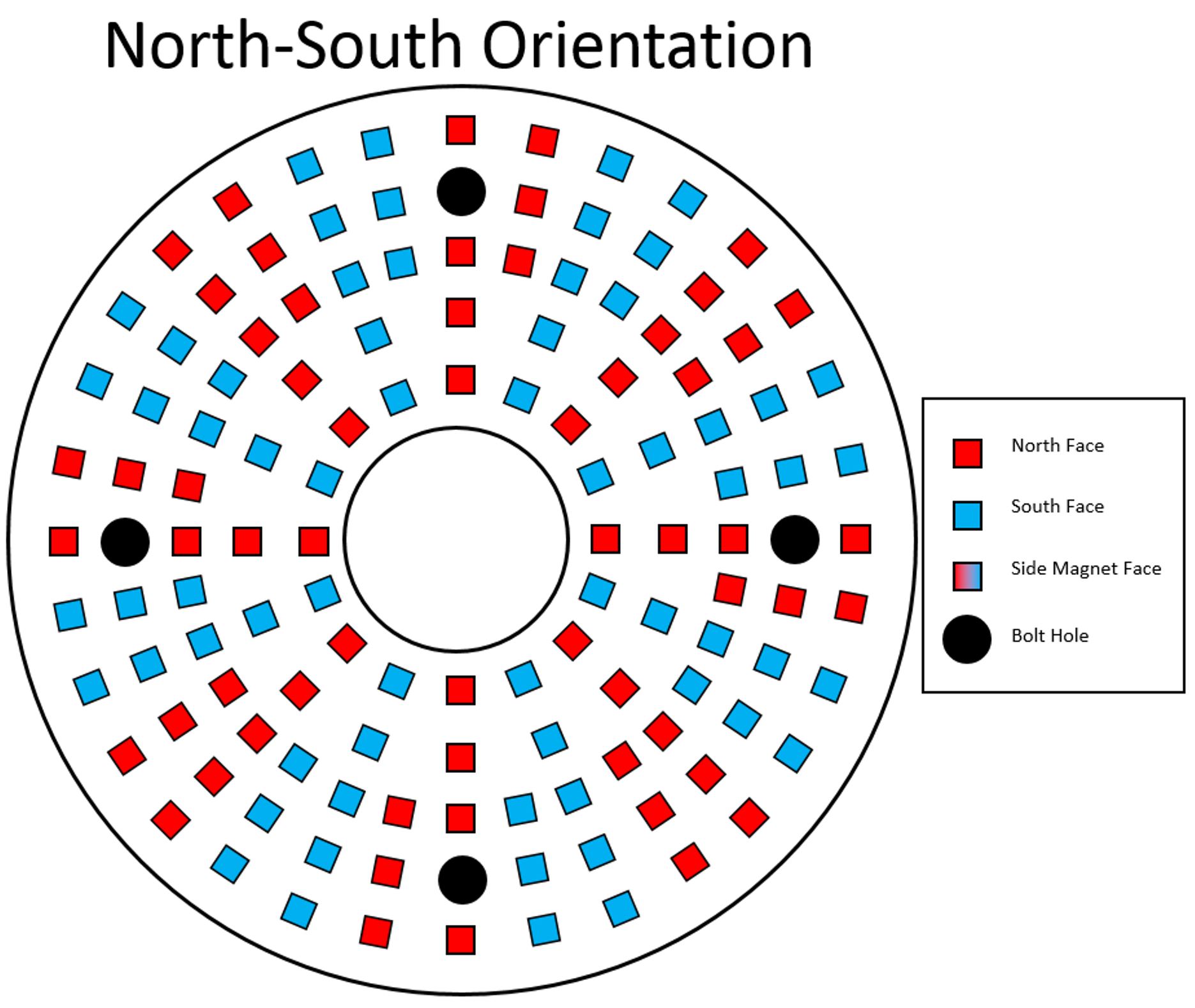

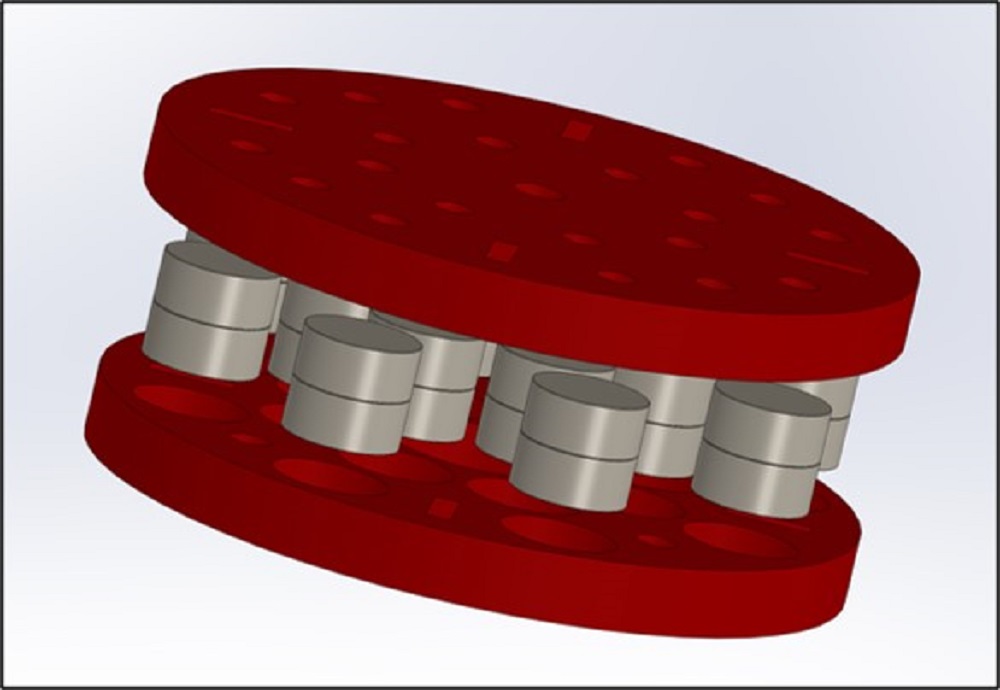

For the magnetic disc and the available materials, the optimal design can be seen below with 2 rings and a 2 stack of the larger magents using the North-South altering orientation.

For the magnetic disc and the available materials, the optimal design can be seen below with 2 rings and a 2 stack of the larger magents using the North-South altering orientation.

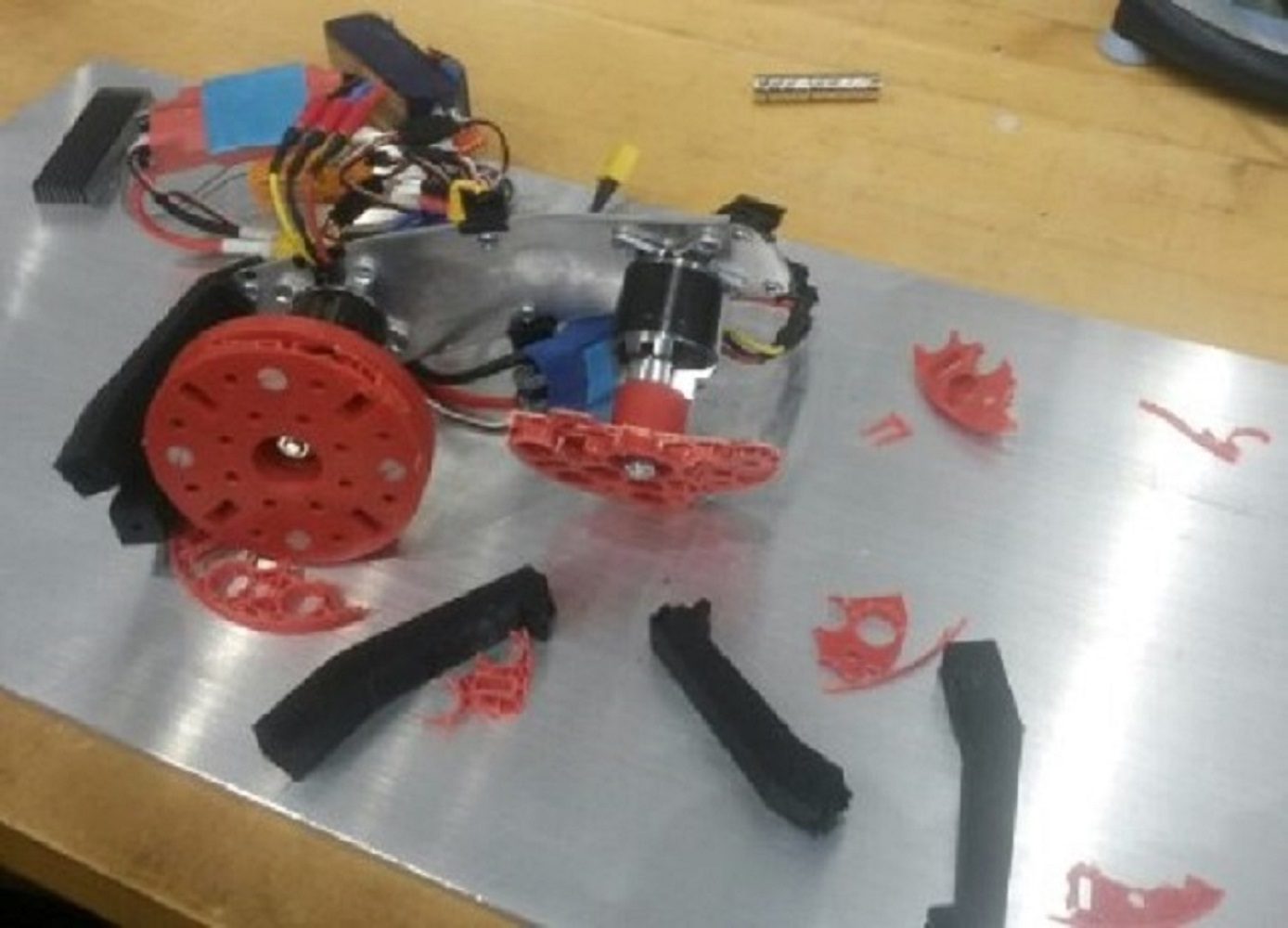

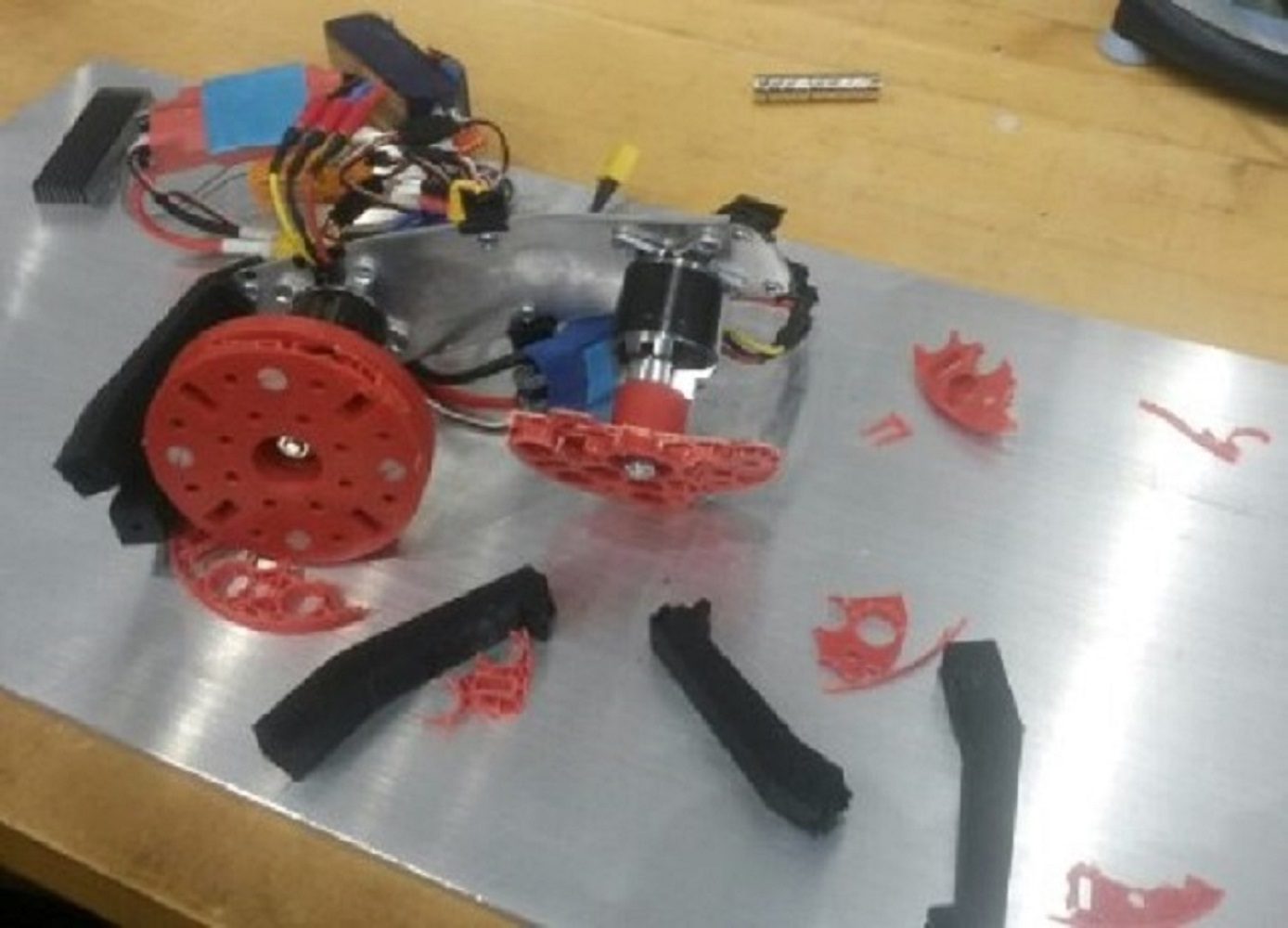

When testing the initial design the RPM's were too high and it caused one of the 3D printed discs to rip apart, sending magnets flying.

When testing the initial design the RPM's were too high and it caused one of the 3D printed discs to rip apart, sending magnets flying.

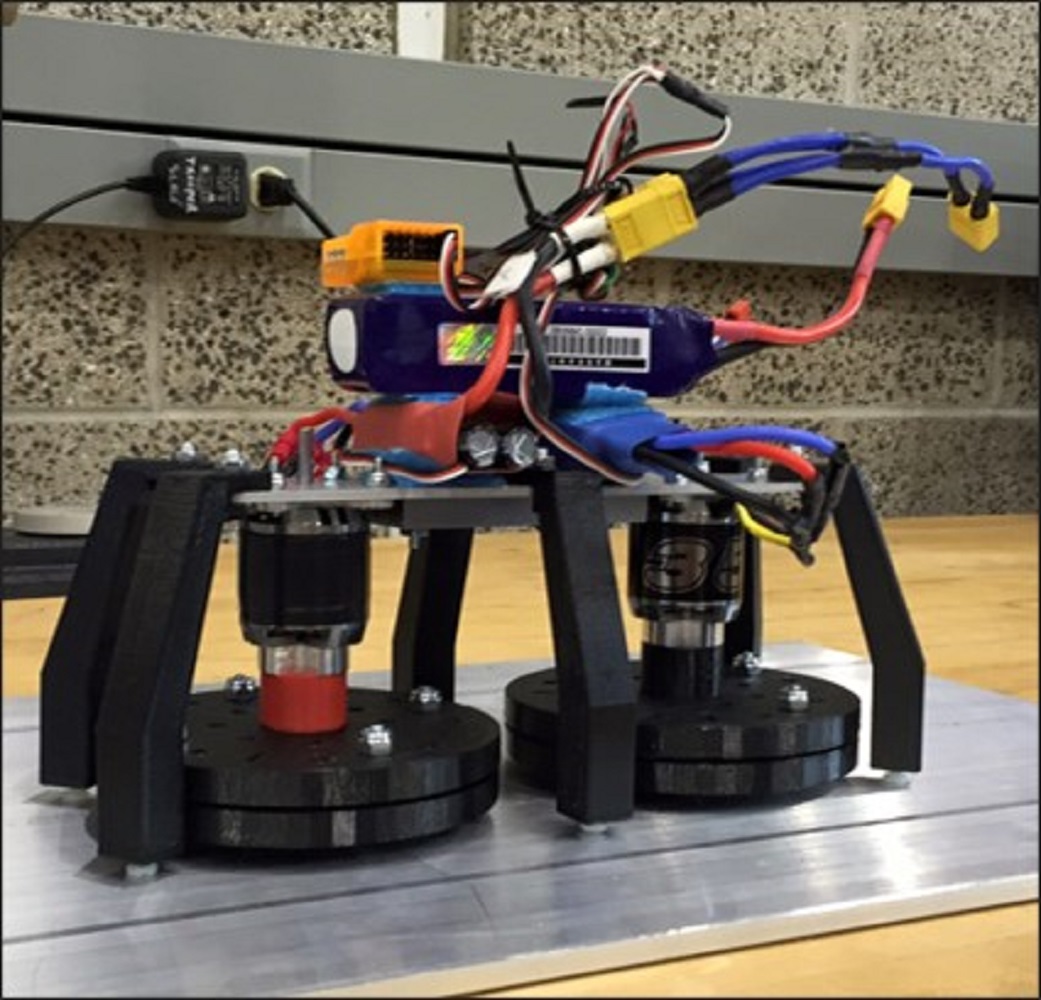

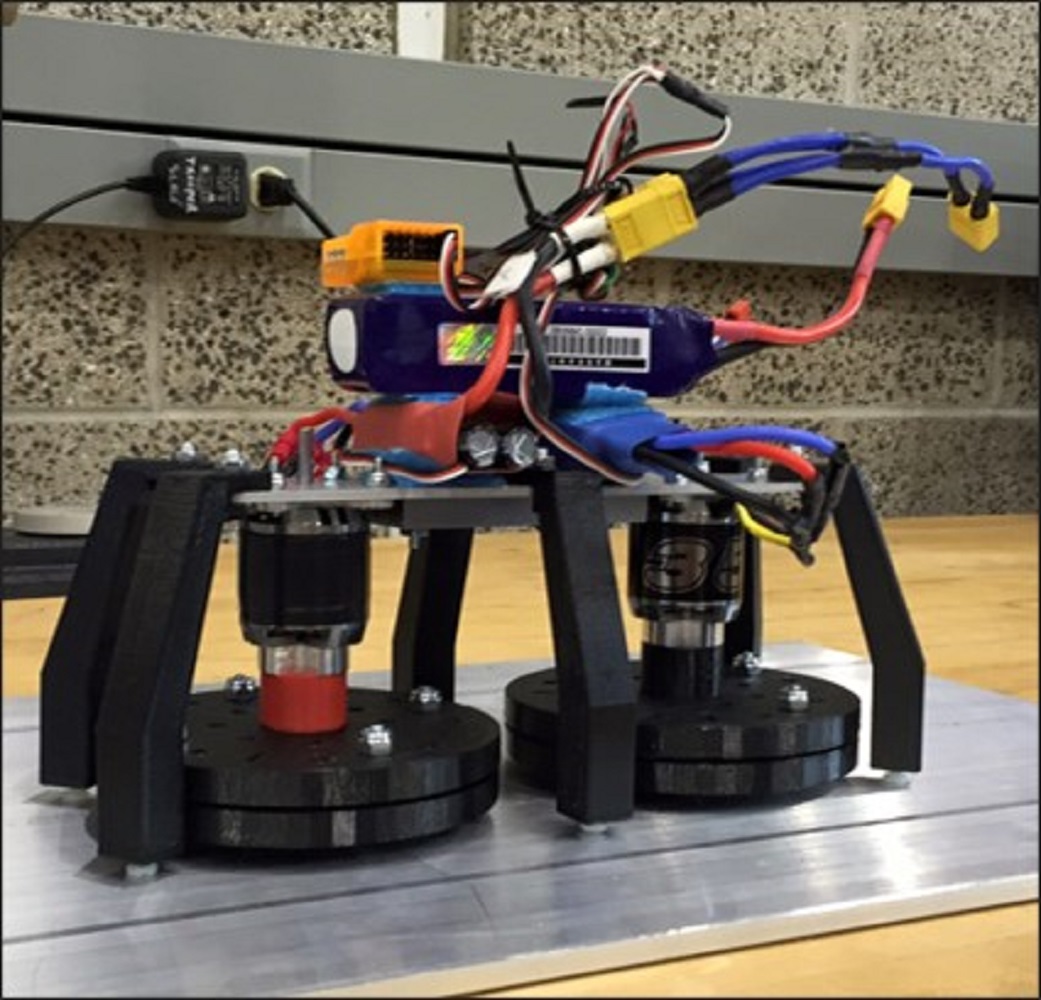

The vehicle was rebuilt with a more robust disc design!

The vehicle was rebuilt with a more robust disc design!

A video showing the vehicle levitating can be seen below. The discs did not spin at the exact same RPM, thus causing the vehicle to spin. It is also important to note the discs are far enough away from each other to spin independently.

This is just a brief overview of the highlights that went into this project.

A video showing the vehicle levitating can be seen below. The discs did not spin at the exact same RPM, thus causing the vehicle to spin. It is also important to note the discs are far enough away from each other to spin independently.

This is just a brief overview of the highlights that went into this project.

The primary concept behind this type of magnetic levitation it to alternate the magnetic field rapidy above a non-ferrous, conductive surface. This can be done by radially alternating the permanent magnet orientation as seen in the below illustration. The Halbach array provides the greatest difference in magnetic fields and would provide the highest repulsion force. There were many factors that needed to be optimized to ensure the maximum repulsion: distance to substrate, rotation rate, substrate material, thickness of substrate, and magnetic disc orientation.

The repulsion force with the 5mm magnetic cubes in the disc did not produce a significant force. I tried going to bigger magnets next.

The repulsion force with the 5mm magnetic cubes in the disc did not produce a significant force. I tried going to bigger magnets next.

I printed a grid with slightly different diameters to select the best press fit.

I printed a grid with slightly different diameters to select the best press fit.

This fixture was made to test the repulsion. in order to optimize the variables.

This fixture was made to test the repulsion. in order to optimize the variables.

A scale was used to see the repulsion force provided. After much testing, the optimal variables that create the highest repulsion force are: closest to substrate, thickest substrate, and the most conductive substrate.

A scale was used to see the repulsion force provided. After much testing, the optimal variables that create the highest repulsion force are: closest to substrate, thickest substrate, and the most conductive substrate.

An unexpected finding is that there is an attaction zone between the repulsion and negligible regions. This was found when the scale kept showing an error. The scale was not zeroed after the substrate was added, thus allowing me to see the weight decrease when the disc spun in the attraction region.

An unexpected finding is that there is an attaction zone between the repulsion and negligible regions. This was found when the scale kept showing an error. The scale was not zeroed after the substrate was added, thus allowing me to see the weight decrease when the disc spun in the attraction region.

The other important finding was that due to the resistance of the rotating magnetic disc (the higher repulsion force, the more resistance), the RPMs would be limited during testing at fixed distances, as seen in the below plot.

This meant landing feet needed to be added to the vehicle that would allow the discs to have minimal resistance when starting up, but not position the vehicle far enough from the substrate to lack the repulsion force needed to levitate the vehicle.

The other important finding was that due to the resistance of the rotating magnetic disc (the higher repulsion force, the more resistance), the RPMs would be limited during testing at fixed distances, as seen in the below plot.

This meant landing feet needed to be added to the vehicle that would allow the discs to have minimal resistance when starting up, but not position the vehicle far enough from the substrate to lack the repulsion force needed to levitate the vehicle.  For the magnetic disc and the available materials, the optimal design can be seen below with 2 rings and a 2 stack of the larger magents using the North-South altering orientation.

For the magnetic disc and the available materials, the optimal design can be seen below with 2 rings and a 2 stack of the larger magents using the North-South altering orientation.

When testing the initial design the RPM's were too high and it caused one of the 3D printed discs to rip apart, sending magnets flying.

When testing the initial design the RPM's were too high and it caused one of the 3D printed discs to rip apart, sending magnets flying.

The vehicle was rebuilt with a more robust disc design!

The vehicle was rebuilt with a more robust disc design!

A video showing the vehicle levitating can be seen below. The discs did not spin at the exact same RPM, thus causing the vehicle to spin. It is also important to note the discs are far enough away from each other to spin independently.

This is just a brief overview of the highlights that went into this project.

A video showing the vehicle levitating can be seen below. The discs did not spin at the exact same RPM, thus causing the vehicle to spin. It is also important to note the discs are far enough away from each other to spin independently.

This is just a brief overview of the highlights that went into this project.